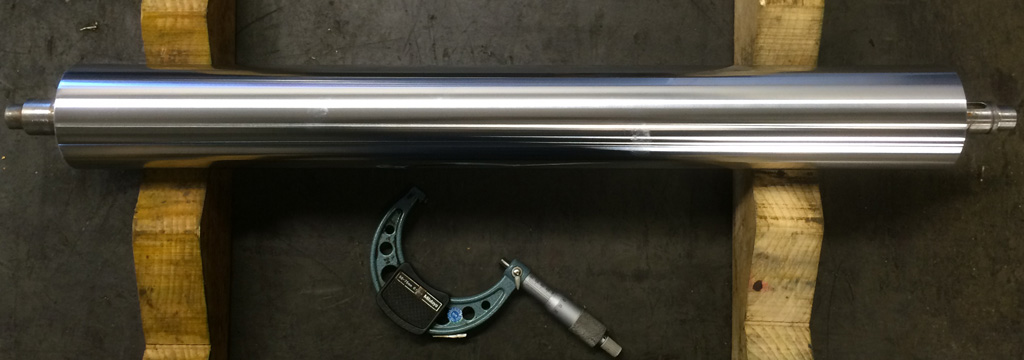

Hard chrome plating

Hard chrome plating is used to reduce friction, improve durability through abrasion tolerance and wear resistance in general, minimize galling or seizing of parts, expand chemical inertness to include a broader set of conditions (especially oxidation resistance) and bulking material for worn parts to restore their original dimensions. It is very hard, measuring between 65 to 69 HRC / 1000 HV.

By applying a very thin layer of hard chrome, usually 20-100 µm, to a metal base material, you combine the characteristics from both materials. The base material can support against mechanical burdening, while the hard chrome plating ensures low friction and high durability.

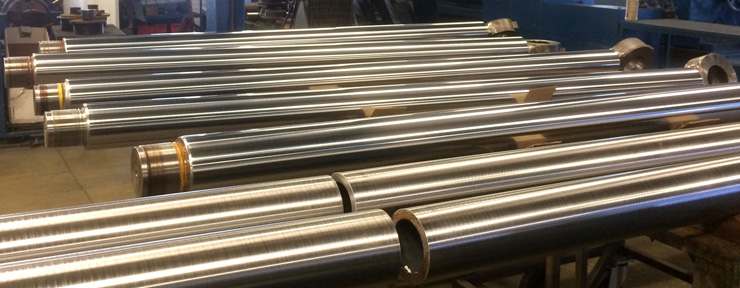

At Lomma Hårdkrom we have three large plating tanks, one for parts up to 13 meters, Ø320 mm, one for parts up to 11 meters, Ø800 mm and one for parts up to 2,2 meter, Ø1400 mm. For smaller parts we have another 3 plating tanks.

We have a lifting capacity of up to 10 tons in the chrome plating process as well as in the pre treatment process.

Characteristics of hard chrome

Approximately the hardness of Corundum

65 to 69 HRC

Low friction

High oxidation resistans

Easily lubricated

Capacity

Diameter/length

Ø1500 mm up to 2,2 meter

Ø800 mm up to 11 meter

Ø320 mm ut to 13 meter

Weight

10 ton

Industries served since 1948

Offshore industry

Paper industry

Steel industry

Foil industry

Packaging industy

Textile industry

And more....